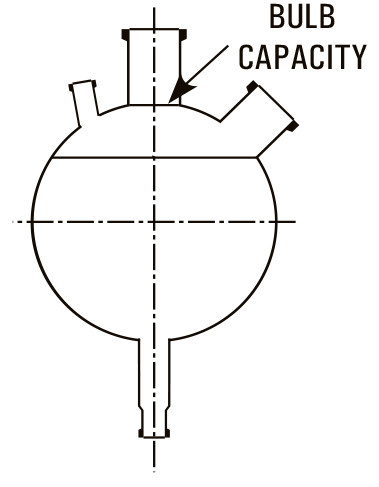

glass spherical vessels made by Goel Scientific Glass Inc. in the USA. Glass spherical vessels are often used in laboratory and industrial settings for a variety of applications such as chemical reactions, mixing, and storage.

Goel Scientific Glass Inc. is a company based in the USA that specializes in the production of high-quality scientific glassware, including glass spherical vessels. They use borosilicate glass, which is known for its resistance to thermal shock and chemical corrosion, making it a popular choice for laboratory and industrial applications.

Glass spherical vessels are specialized glassware used in laboratory and industrial settings for various purposes. They are a type of glass container that is spherical in shape, and they come in a range of sizes and capacities.

One of the main benefits of glass spherical vessels is their shape, which provides a more even distribution of pressure and allows for thorough mixing of the contents. This is especially important for chemical reactions, where uniform mixing is essential for obtaining accurate results.

Glass spherical vessels are typically made from borosilicate glass, which is a type of glass that is highly resistant to thermal shock and chemical corrosion. This makes it an ideal material for use in laboratory and industrial applications where high temperatures and harsh chemicals are often involved.

Glass spherical vessels come in a range of sizes, from small vessels that can hold just a few milliliters of liquid to large vessels that can hold several liters. They may also be fitted with various accessories, such as stoppers, ports, and stirrers, to make them more versatile and adaptable to different applications.

Some of the common applications of glass spherical vessels include chemical reactions, mixing, storage, and distillation. They are often used in the pharmaceutical, biotechnology, and chemical industries, as well as in research laboratories and academic settings.

Overall, glass spherical vessels are an essential piece of glassware for many laboratory and industrial applications. Their shape, durability, and chemical resistance make them an ideal choice for a wide range of purposes, from chemical reactions to storage and mixing.

2

| Nominal Capacity (Ltrs.) | Maximum Pressure (Bar) |

| 5 | 1 |

| 5 | 0.8 |

| 20 | 0.7 |

| 50 | 0.5 |

| 100 | 0.4 |

| 200 | 0.3 |

| 300 | 0.2 |

| 500 | 0.1 |

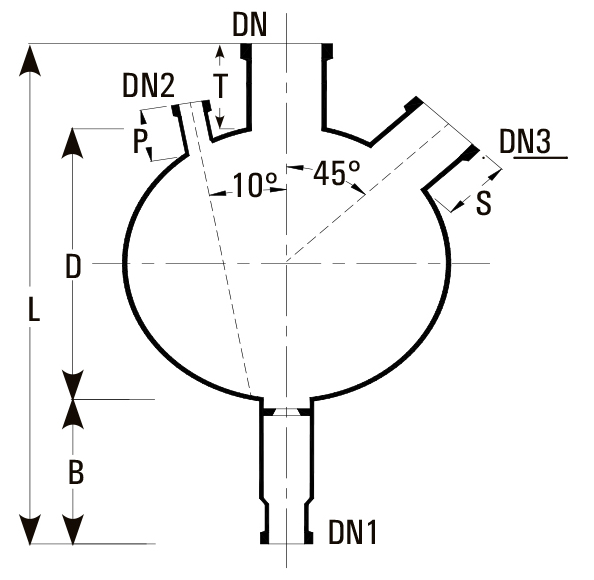

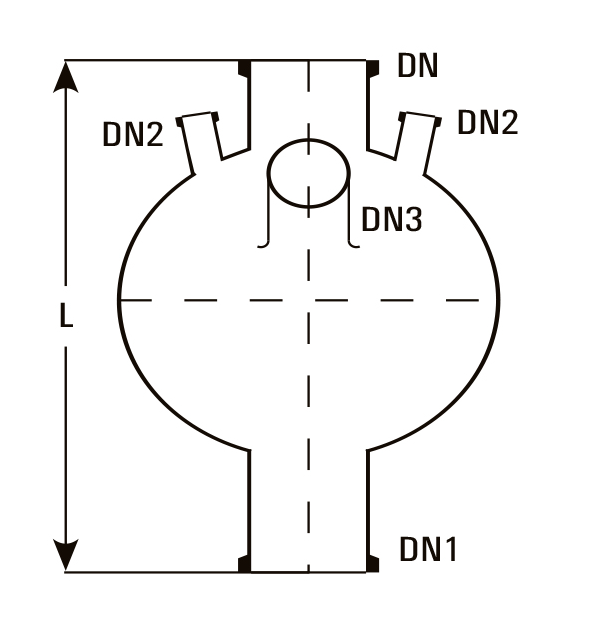

| Nominal Capacity(Ltrs.) | L | L | D | DN | T | DN1 | B | DN2 | P | DN3 | S |

| 5 | 425 | 425 | 223 | 50 | 85 | 25 | 125 | 25 | 50 | 40 | 75 |

| 10 | 500 | 500 | 285 | 80 | 100 | 25 | 125 | 25 | 50 | 40 | 75 |

| 20 | 575 | 575 | 350 | 100 | 100 | 25 | 125 | 25 | 50 | 40 | 75 |

| 50 | 800 | 800 | 490 | 150 | 150 | 40 | 200 | 40 | 75 | 100 | 100 |

| 100 | 900 | 900 | 600 | 225 | 150 | 40 | 200 | 40 | 75 | 100 | 100 |

| 200 | 1100 | 1100 | 750 | 300 | 250 | 40 | 200 | 40 | 75 | 100 | 100 |

| 300 | 1175 | 1175 | 860 | 400 | 250 | 50 | 175 | 50 | 75 | 100 | 100 |

| 500 | 1400 | 1400 | 1000 | 450 | 250 | 50 | 200 | 50 | 75 | 150 | 165 |

In addition to their use in chemical reactions, mixing, storage, and distillation, glass spherical vessels can also be used for other applications. For example, they may be used in the production of specialty chemicals, as well as in the manufacturing of pharmaceuticals and biologics.

Glass spherical vessels are also commonly used in research and development settings, where they may be used to study the properties of materials under different conditions. This may include experiments involving high temperatures, high pressures, or corrosive chemicals.

When using glass spherical vessels, it is important to handle them with care to avoid breakage. This may include using appropriate clamps and stands, avoiding sudden changes in temperature, and using protective equipment such as gloves and safety glasses.

In addition to their durability and chemical resistance, glass spherical vessels also have the advantage of being transparent, which allows for easy observation and monitoring of the contents. This is especially important in chemical reactions, where precise timing and monitoring of the reaction is essential.

Overall, glass spherical vessels are an important piece of laboratory and industrial equipment that is widely used for a variety of applications. They offer many advantages over other types of glassware, including their shape, durability, chemical resistance, and transparency, making them a popular choice for many different purposes.

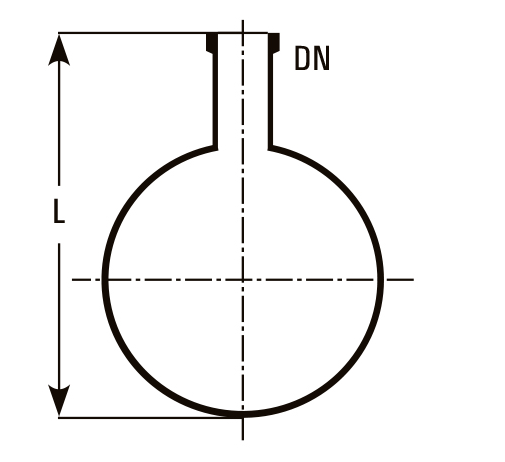

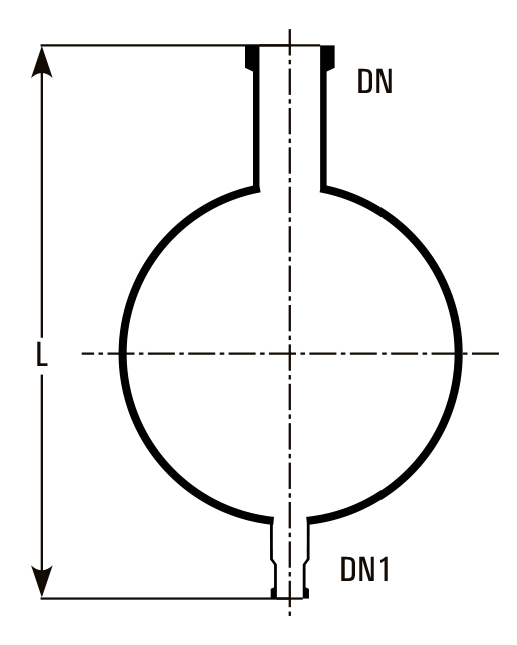

3 Single Neck Spherical Vessel

| Cat.Ref. | Nominal Capacity | L | DN |

| VSA5 | 5 L | 300 | 50 |

| VSA10 | 10 L | 375 | 80 |

| VSA20 | 20 L | 450 | 100 |

| VSA50 | 50 L | 600 | 150 |

| VSA100 | 100 L | 700 | 225 |

| VSA200 | 200 L | 900 | 300 |

| VSA300 | 300 L | 1000 | 400 |

| VSA500 | 500 L | 1200 | 450 |

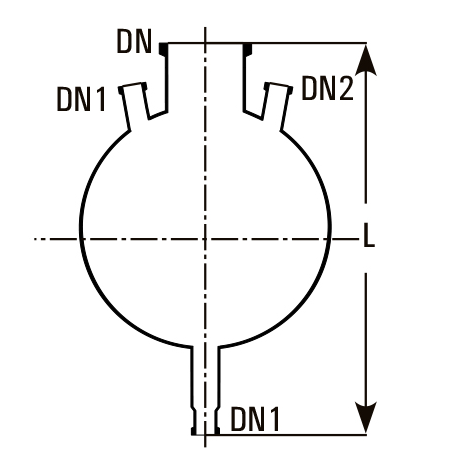

4 Three Neck Bottom Outlet Spherical Vessels

| Cat.Ref. | Nominal Capacity | L | DN | DN1 | DN2 |

| VSM5 | 5 L | 450 | 50 | 25 | 25 |

| VSM10 | 10 L | 500 | 80 | 25 | 25 |

| VSM20* | 20 L | 575 | 100 | 25 | 25 |

| VSM50* | 50 L | 800 | 150 | 40 | 40 |

| VSM100 | 100 L | 900 | 225 | 40 | 40 |

| VSM200 | 200 L | 1100 | 300 | 40 | 40 |

| VSM300 | 300 L | 1175 | 400 | 50 | 50 |

| VSM500 | 500 L | 1400 | 450 | 50 | 50 |

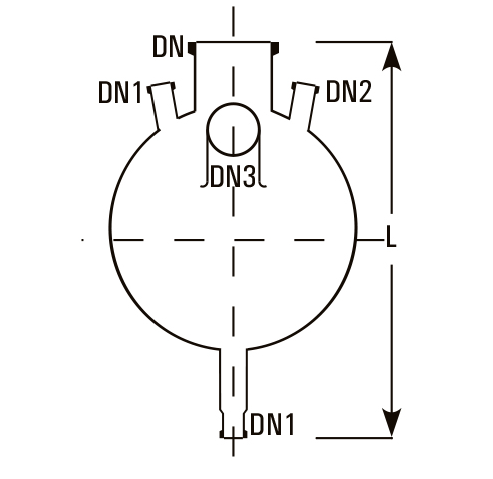

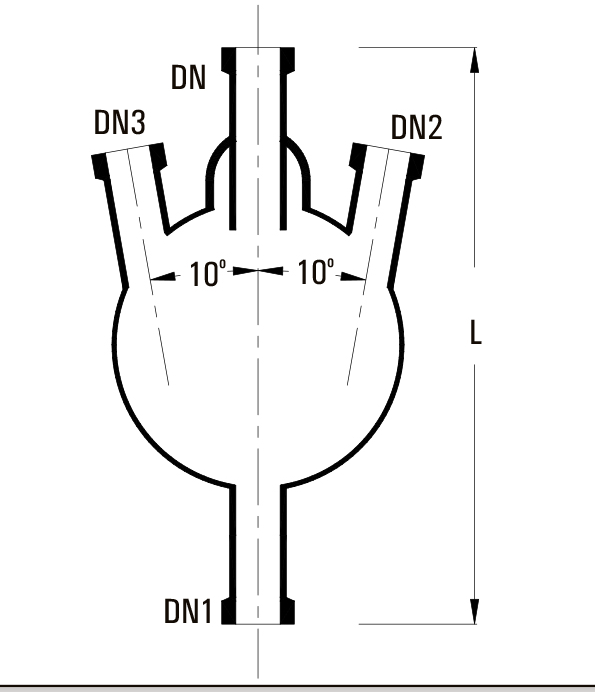

5.FOUR NECK BOTTOM OUTLET SPHERICAL VESSELS

| Cat.Ref. | Nominal Capacity | L | DN | DN1 | DN2 | DN3 |

| VSPL5 | 5 L | 425 | 50 | 25 | 25 | 40 |

| VSPL10 | 10 L | 500 | 80 | 25 | 25 | 40 |

| VSPL20 | 20 L | 575 | 100 | 25 | 25 | 40 |

| VSPL50 | 50 L | 800 | 150 | 40 | 40 | 100 |

| VSPL100 | 100 L | 900 | 225 | 40 | 40 | 100 |

| VSPL200 | 200 L | 1100 | 300 | 40 | 40 | 100 |

| VSPL300 | 300 L | 1175 | 400 | 50 | 50 | 100 |

| VSPL500 | 500 L | 1400 | 450 | 50 | 50 | 150 |

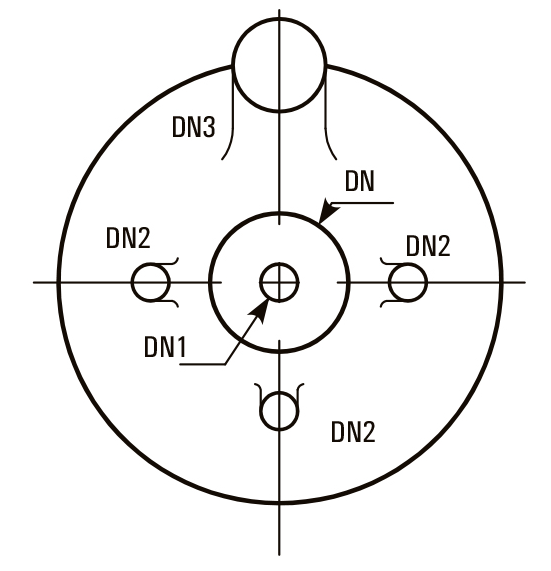

FIVE NECK BOTTOM OUTLET SPHERICAL VESSEL

| Cat.Ref. | Nominal Capacity | L | DN | DN1 | DN2 | DN3 |

| VS 5 | 5 L | 425 | 50 | 25 | 25 | 40 |

| VS 10 | 10 L | 500 | 80 | 25 | 25 | 40 |

| VS 20 | 20 L | 575 | 100 | 25 | 25 | 40 |

| VS 50* | 50 L | 800 | 150 | 40 | 40 | 100 |

| VS 100* | 100 L | 900 | 225 | 40 | 40 | 100 |

| VS 200* | 200 L | 1100 | 300 | 40 | 40 | 100 |

| VS 300 | 300 L | 1175 | 400 | 50 | 50 | 100 |

| VS 500 | 500 L | 1400 | 450 | 50 | 50 | 100 |

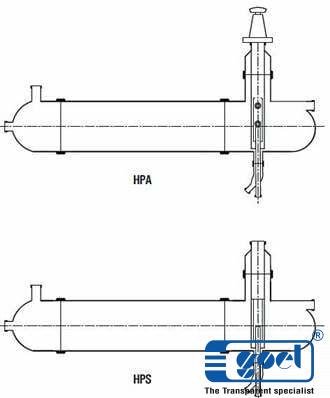

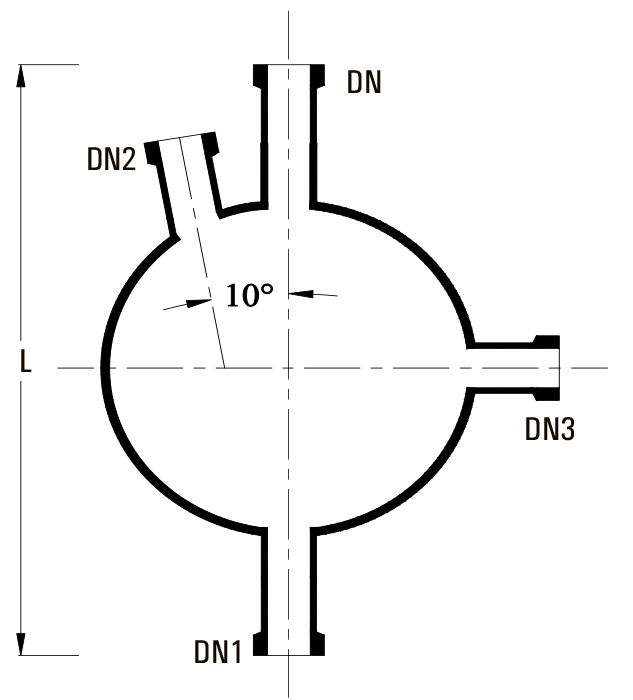

SPHERICAL VESSELS WITH NOZZLE AT 90°

These vessels are used in Circulatory Boiler System and are to be supported on a vessel holder. More nozzles can be provided on the equator on request for special requirements.

| Cat.Ref. | Nominal Capacity | L | DN | DN1 | DN2 | DN3 |

| VSD5 | 5 L | 425 | 50 | 25 | 25 | 50 |

| VSD10 | 10 L | 500 | 80 | 25 | 25 | 50 |

| VSD20 | 20 L | 575 | 100 | 25 | 25 | 50 |

| VSD50 | 50 L | 800 | 150 | 40 | 40 | 80 |

| VSD100 | 100 L | 900 | 225 | 40 | 40 | 80 |

| VSD200 | 200 L | 1100 | 300 | 40 | 40 | 150 |

| VSD300 | 300 L | 1175 | 400 | 50 | 50 | 150 |

| VSD500 | 500 L | 1400 | 450 | 50 | 50 | 150 |

SPHERICAL CYCLONES

Cyclones can be used for the separation of droplets and solids from gases and vapours. Cyclones are to be supported on a vessel holder. A dip pipe should be used on the top neck.

| Cat. Ref. | Nominal Capacity | L | DN | DN1 | DN2 | DN3 |

| VSCY5 | 5 L | 425 | 50 | 25 | 25 | 40 |

| VSCY10 | 10 L | 500 | 80 | 25 | 25 | 40 |

| VSCY20 | 20 L | 575 | 100 | 25 | 25 | 50 |

| VSCY50 | 50 L | 800 | 150 | 40 | 40 | 50 |

Spherical cyclones are a type of cyclone separator that are commonly used in various industries for gas-solid or liquid-solid separation. Cyclone separators are devices that utilize centrifugal force to separate particles from a gas or liquid stream based on their size, shape, and density. Spherical cyclones have a spherical shape and are designed to achieve higher separation efficiency than conventional cyclone separators.

The design of spherical cyclones is based on the principle that the centrifugal force generated by the high-speed rotation of the gas or liquid stream causes the particles to move towards the outer wall of the separator. The particles are then collected at the bottom of the separator by gravity and discharged through a separate outlet. The gas or liquid stream is then discharged from the top of the separator.

Spherical cyclones have several advantages over conventional cyclone separators. First, their spherical shape provides a more uniform distribution of the gas or liquid stream, which results in a more even distribution of the particles. Second, the spherical shape allows for a more efficient use of space, as they can be placed in a compact configuration. Third, the spherical shape allows for easier cleaning and maintenance, as there are no corners or edges where particles can accumulate.

Spherical cyclones can be used in a variety of applications, including the separation of dust and particles from air streams in industrial processes, the separation of solids from liquids in wastewater treatment plants, and the separation of oil and gas from produced water in the oil and gas industry. They are also used in the food processing industry to separate solids from liquids in the production of dairy products and beverages.

One potential disadvantage of spherical cyclones is that they can be more expensive to manufacture than conventional cyclone separators. However, the increased efficiency and other advantages of spherical cyclones often justify the higher cost.

In summary, spherical cyclones are an effective and efficient type of cyclone separator that can be used in a variety of industries for gas-solid or liquid-solid separation. Their unique spherical shape provides several advantages over conventional cyclone separators, including a more uniform distribution of the gas or liquid stream, more efficient use of space, and easier cleaning and maintenance. While they may be more expensive to manufacture, their increased efficiency and other advantages often make them a worthwhile investment.

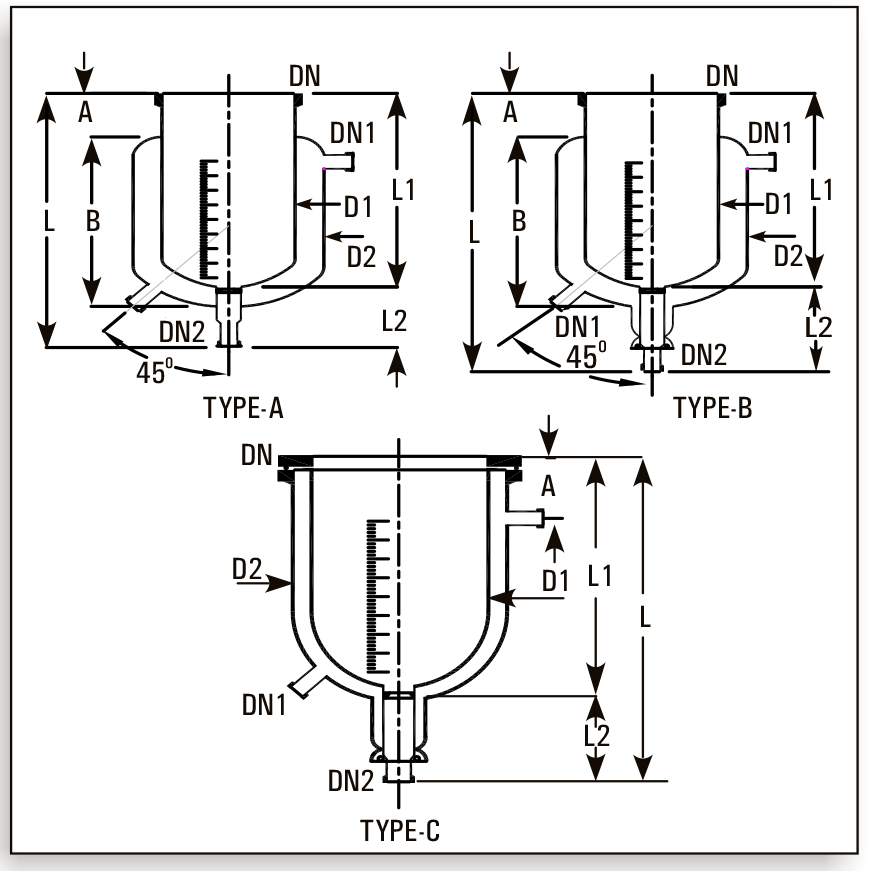

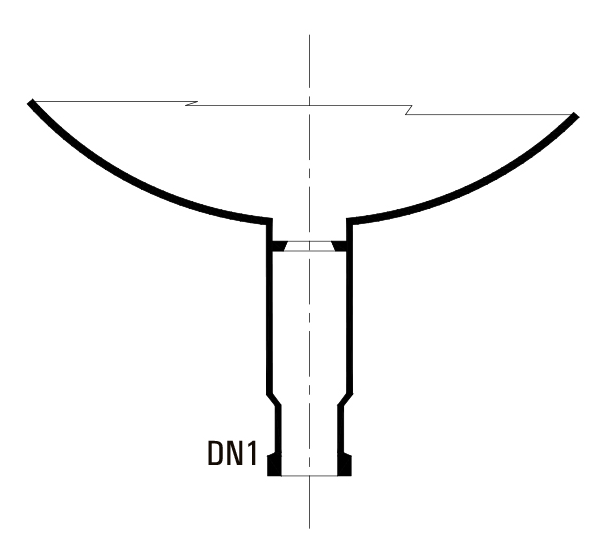

ADDITION VESSELS

These vessels are provided with a short bottom outlet. These should be supported on a vessel holder/ holding ring.

| Cat.Ref. | Nominal Capacity | L | DN | DN1 |

| VA5* | 5 L | 375 | 360 | 50 |

| VA10* | 10 L | 435 | 80 | 25 |

| VA20* | 20 L | 510 | 100 | 25 |

| VA50 | 50 L | 675 | 150 | 40 |

| VA100 | 100 L | 775 | 225 | 40 |

| VA200 | 200 L | 975 | 300 | 40 |

| VA300 | 300 L | 1075 | 400 | 50 |

| VA500 | 500 L | 1400 | 450 | 50 |

SPHERICAL VESSELS WITH WIDE BOTTOM OUTLET

These vessels are generally used to fit immersion exchangers in the bottom. Special heating mantle or bath should be used if used with.

| Cat.Ref. | Nominal Capacity | L | DN | DN1 | DN2 | DN3 |

| VSR50 | 50 L | 750 | 150 | 150 | 40 | 100 |

| VSR100 | 100 L | 850 | 225 | 150 | 40 | 100 |

| VSR200 | 200 L | 1050 | 300 | 150 | 40 | 100 |

| VSE50 | 50 L | 800 | 150 | 225 | 40 | 100 |

| VSE100 | 100 L | 900 | 225 | 225 | 40 | 100 |

| VSE200 | 200 L | 1100 | 300 | 225 | 40 | 100 |

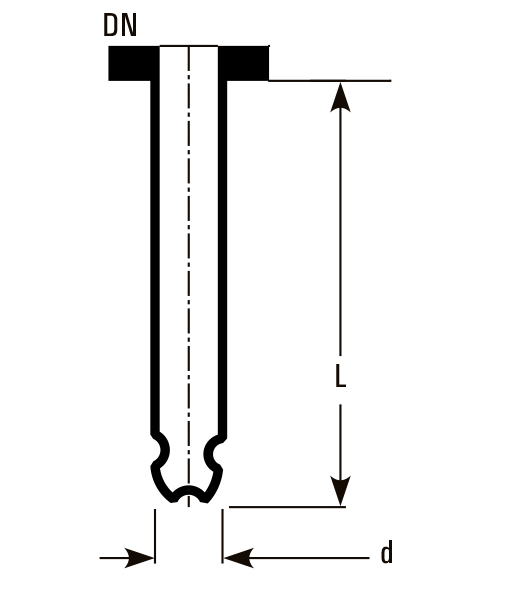

VESSELS WITH BOTTOM OUTLET VALVE SEAT

To fit a bottom outlet valve (BAL type) all spherical and cylindrical vessels can be supplied with valve seat in bottom outlet. For this, Add a suffix “/B” to the catalogue reference of a vessel, for e.g. ‘VSL50’ should be mentioned as ‘VSL50/B’.

NOTES ON USE OF SPHERICAL VESSELS :

1. Generally, the centre nozzle, referred as DN in all types of vessels, is used for either stirrer fixing or, if stirrer is not fixed, for vapour outlet.

2. The bottom outlet, referred as DN1 in all types, is used for drain. However, in type VSR & VSE, it is also used for fixing immersion heat exchanger.

3. The small side nozzles, referred as DN2 in all types, are used (a) to fix thermometer pocket or

(b) to fix dip pipe for liquid inlet or,

(c) to fix sparger for gas purging or,

(d) to fix vacuum control or vent valve or,

(e) for solid addition.

4. The bigger side nozzle, referred as Dn3, is used for vapour outlet where stirrer is fixed on centre neck. It can also be used for cleaning in case centre neck is used for vapour outlet.

5. Vessels having long bottom outlet, viz VSM, VSPL, VSL, VS etc, can be supported in a heating mantle of heating bath. However, vessels having short bottom outlet, viz VSD, VSCY, VR, VA etc. are to be supported on a vessel holder only. In case of vessels upto 20L size, vessel holding rings can be used instead of vessel holder.

*marked items are available fast.