Lab glass reactors are incredibly efficient devices when it comes to mixing, dispersing, homogenizing, and optimizing chemical reactions on a laboratory scale. They feature corrosion-resistant qualities, a clear view of the reaction process, and good performance in vacuum and atmospheric pressures. These reactors are popular for many applications because they increase productivity, precision, and total repeatability.

Best Laboratory Glass Reactor Manufacturers & Suppliers

Lab glass reactors are premium, fire-resistant reactors that provide the best possible process performance in lab settings. They are connected to auxiliary devices such as Nox Gas Scrubbers, Distillation unites, and Agitated Nutsche Filters. Processing of acids and Solvents Recovery in a sealed reaction tank is made safe by the fireproof design. Goel Scientific Glass has experience building reactors to meet customer specifications and provides a large selection of vessel alternatives. Certainly, their highly qualified experts put in endless effort to design and produce glass reactors in accordance with requirements. In most glass plants, vessels are used as reactors, receivers, separators, and measuring or feed vessels.

What is a Lab Glass Reactor?

Glass reactors are utilized in the chemical and pharmaceutical industries because they are compatible with a wide variety of substances. An agitator is built within the reactor, a container that allows chemicals to mix in a controlled setting.

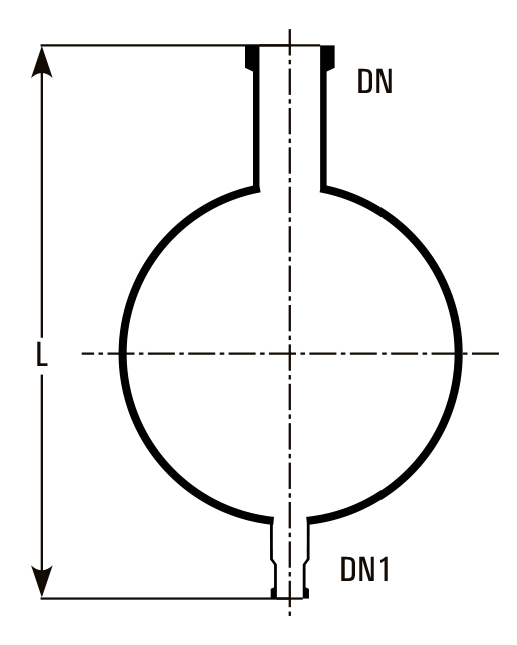

The reactor may function in a variety of temperatures and under pressure. The reactor’s upper part facilitates the connection of the process nozzles, which introduce chemicals and gases as needed and enable cleaning head nozzles. They come in a variety of sizes, but the standard range is 5 Ltr to 100 Ltr. Glass Reactor is available in Spherical Shape from 5 to 500 Ltr and in Cylindrical Shape from 5 to 500-Ltr capacity. Cylindrical vessels can be supplied with metal/glass jackets too. In most glass plants, vessels are used as reactors, receivers, separators, and measuring or feed vessels.

Types of Lab Glass Reactors

Stirrer with suitable mechanical seal/stuffing box/magnetic seal.

Volume of Lab Glass Reactor: 500 mL to 5000 ml.

There are three types of reactors: single, double, and triple walls.

Operating Pressure: 0.5 bar (g) to full vacuum

-50°C to +180°C is the operating temperature range.

Thermal shock resistance (Dt): triple-walled reactors at 60°C and double-walled reactors at 11

High pressure Glass Reactor

A High – pressure Glass Reactor is a specialized vessel designed for chemical reaction elevated pressure, achieved by the reaction itself or externally supplied source like hydrogen. Operating at temperatures above solvent boiling points, these reactors impact reaction dynamics by increasing concentration $ collision frequency among molecules, accelerating reactions.

Versatile Uses

Widely used in industries requiring precise control over reaction, such as organic synthesis & pharmaceutical development. There control environment facilities effects efficient exploration & optimizatation of various chemical reaction.

How Lab Glass Reactors Work

Reactors function by letting chemicals into a confined area and stirring them using an agitator in the middle. Baffles are usually incorporated into the vessel to guarantee enough internal turbulence to mix and blend the chemicals and activate the reactor. Normal chemical reactions occur when the right catalysts, chemicals, pressure, temperature, and contact time are present. Furthermore, the final result could be liquid or solid.

Applications and Industries

Glass reactors are useful in the biotechnology, Chemical, & pharmaceutical R & D. They can be used for many different things, such as:

- Chemical synthesis: The chemical and pharmaceutical industries employ glass reactors to synthesize a variety of compounds.

- Polymerization: Resins, adhesives, and plastics are among the materials that may be polymerized in glass reactors.

- Distillation: Valuable compounds are recovered, and solvents are distilled using glass reactors via fractional distillation.

- Crystallization: Chemical compounds can crystallize in glass reactors.

- Extraction: Plant materials are extracted, natural products are isolated, and compounds are purified using glass reactors Via steam & Vacuum Distillation method

- Wiping Film Evaporator: Sensitive products like Vitamins, Hormones enzymes, or aromatic substance reaction under vacuum forming thin film to reduced time using glass Column / reactor

Advantages of Laboratory Glass Reactors

1. Corrosion resistance

Borosilicate glass is very useful for reactors since it doesn’t rust or break down too easily, even after being used repeatedly.

2. Reduced maintenance run

Businesses may skip routine maintenance procedures because of their extraordinary resistance to corrosion, which saves them money and time.

3. Thermal resistance

The low thermal reaction rate of borosilicate glass is well known, and this property is essential for processes in glass reactors that call for a broad range of heat variations. This material is excellent for glass reactors because of its ability to withstand heat.

4. Physical durability

In the glass sector, producers of borosilicate glass provide reactors with a revolutionary edge. Because of their physical durability, these reactors are used more often in scientific and industrial settings. They are also used as sturdy cutlery in homes and restaurants.

5. Inertness

Given its inertness to various chemicals and lack of reactivity, borosilicate glass is an excellent material for lab ware. Furthermore, it is utilized in glass reactors and is perfect for storage and research. For better product quality, other chemical producers require equipment with this functionality. Because of this, borosilicate glass is the material of choice for making lab ware.

6. Visibility

One of this material’s main advantages is its visibility. It improves dependability and makes it perfect for reactor construction by enabling a clear view of the reaction and process inside the reactor.

Laboratory Glass Reactor Manufacturers and Suppliers

Some of the best lab glass reactor manufacturers and suppliers

- Goel Scientific Glass: Toronto, ON

- Across International: Livingston, NJ

- Chemglass, Inc.: Vineland, NJ

- De Dietrich Process Systems, Inc.: Mountainside, NJ

- Citrogene, Inc.: San Jose, CA

Choosing the Right Laboratory Glass Reactor for Your Needs

The following elements should be taken into account when choosing a glass reactor for your lab:

- Volume: A range of volumes, from a few millilitres to several liters, are available for glass reactors. Your reactions’ scale will determine how big of a reactor you require.

- Jacket type: Glass reactors can have single or double jackets. While a double jacket provides more exact temperature control, a single jacket allows for heating or cooling.

- Agitation: To guarantee adequate reactant mixing, the majority of glass reactors include a stirrer. The viscosity of the materials you are dealing with will determine the kind of stirrer you require.

- Accessories: Reflux dividers, distillation heads, condensers, and other accessories are available for glass reactors.

Why Choose Goel Scientific for a Lab Glass Reactor?

Leading borosilicate glass producer Goel Scientific provides top-notch machinery and goods to many nations. Leading the business in sales, they supply in elite glass reactors to esteemed facilities all over World Our customers have acknowledged the outstanding quality and reach of their glass reactors. The industry makes extensive use of our glass reactors. Overall, Goel Scientific Glass Inc is a reliable and trusted manufacturer of glass reactors and other laboratory glassware. Its commitment to quality, innovation, and customer service has made it a preferred supplier for customers in various industries Know more, Contact us!

FAQs:

1. Are there different types of lab glass reactors, and how do I choose the right one for my needs?

Think about the following while selecting your next-line reactor:

- Class of insulation

- A minimum heat increase of 115°C is to be expected.

- Request the development of a vacuum pressure impregnation system.

2. What safety precautions should I take when working with lab glass reactors?

Always wear the proper safety gear, such as gloves, a face shield, and safety goggles. When feasible, use glassware with a PVC coating. Cover flasks, drawers, and desiccators with mesh or tape if not available.

3. How do I clean and maintain a lab glass reactor?

More satisfying results will come from using a cleaning powder with a little abrasive effect on very unclean glassware. Certainly, a brush can thoroughly clean every portion of the glassware throughout the washing process.

4. What size options are available for Lab Glass Reactors?

Goel Scientific Glass supplies Bench top Lab Glass Reactors. This contains 5000L to 50L containers with Single, Double & Triple walls.

5. Can I customize a glass reactor to meet my needs or add additional features?

Yes. Lab Reactors are built from a variety of materials according to your needs. All you have to do is search for the Custom laboratory glassware manufacturer near me, and Goel Scientific will be available at your service.

Need top-notch laboratory glassware manufacturers? Goel Scientific Glass a reliable and renowned name when it comes to top-grade lab equipment, including laboratory glass reactors. Contact us today for a quote.

6. Why Choose Goel – A Borosilicate Pressure Reactor?

When considering a pressure reactor for your specific industrial or laboratory needs, the Goel- A Borosilicate Company Pressure Reactor stands out as a superior choice. Meticulously designed by industry experts, this reactor is engineered to offer users exceptional control over pressure, high performance, and utmost safety. Goel – A Borosilicate Company leverages its extensive expertise in scientific glass fabrication and its proficiency in catering to diverse chemical processing industries to create a state-of-the-art system with several distinct advantages:

Salient Features

- Glass Reactors made from Germany Raw Material.

- Lab Reactor system suitable for most bench top fume hoods.

- Stirrer with suitable mechanical seal/stuffing box/magnetic seal.

- Skid Mounted and quick release clamp for easy installation & removable of glassware.

- Suitable for vacuum condition

- Flush bottom with minimum dead volume.

- Overhead Stirrer geared motor with built-in speed controller & display.

- Measurement Marking on the vessel.

- Interchangeable Stirrer anchor, propeller, turbine Digital temperature indicator

- Reactors equipped with the flush bottom valve of the special type to ensure leak-free sealing over entire temperature rang.

All These Reactors are designed GMP.

Optional:Hot water/oil circulator, Chiller, heating /Cooling system ,Vacuum Pump, PH probe with transmitter, Pressure Gauge.