Solvent recovery is often an overlooked aspect of process design, yet it frequently represents a significant operational cost. In many pharmaceutical and chemical processing facilities, recovered solvents account for a substantial portion of material expenses. However, the equipment used to recover them is often misaligned with the actual scale of production.

A mismatch here creates operational inefficiencies: highly skilled chemists may waste hours manually tending to small-batch equipment, or a facility might expend excessive energy on a continuous system that is too large for the required output.

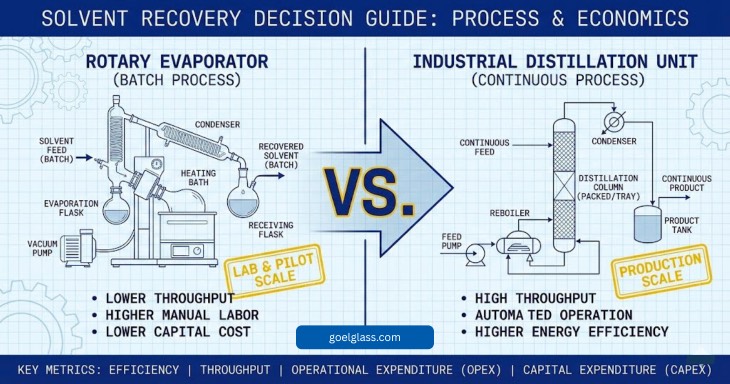

The decision between a Rotary Evaporator (Rotavap) and an Industrial Distillation Unit is not about which machine is superior, but rather which system matches the throughput economics of the facility. For facilities at varying scales, aligning infrastructure with production goals is critical to maintaining margins.

Phase 1: The Flexibility Audit (The Rotary Evaporator)

Scenario : The facility is a Kilo Lab or Pilot Plant. The team handles multiple products, and preventing cross-contamination is a priority.

The Engineering Check:

- Do you change solvents daily?(e.g : Methanol in the morning, Toluene in the afternoon?)

- Is the residue heat-sensitive?(Do you need to keep bath temperatures low to protect an Active Pharmaceutical Ingredient?)

- Is the batch volume under 50L?

If the answer is YES:

The process likely requires rotary evaporator for solvent removal. Its primary mechanism involves creating a thin film of solvent on the inner surface of a rotating flask. This maximizes the surface area for evaporation while maintaining a gentle temperature profile. It is the standard for versatility: easy to clean, simple to inspect, and quick to reset for different chemicals.

- The Scaling Limit :Attempting to use a bank of multiple rotavaps to match the output of a single continuous column is a common error. The labor cost of manual filling and emptying flasks often outweighs the equipment savings.

- The Standard : For facilities operating under strict regulatory frameworks, ensuring equipment meets compliance standards specifically regarding vacuum seal integrity in volatile environments is essential.

Phase 2: The Throughput Audit (The Industrial Distillation Unit)

Scenario : The process is moving to production. There are 200L+ of mixed solvent waste accumulating every shift. The rotavap is running continuously but cannot keep up with generation.

The Engineering Check :

- Is the process continuous?(Does it require a steady feed rate rather than batches per shift?)

- Is high purity separation required? (Are you separating solvents with close boiling points?)

- Is vertical space available?(Can the facility accommodate the height of a packed column?)

If the answer is YES:

It is likely time to install standard distillation units. Unlike the single-stage evaporation of a rotavap, these systems are engineered for scale.

- The Complexity Factor:For basic bulk solvent stripping where high purity isn't critical, simple distillation units may suffice. However, if the goal is separating complex mixtures (like Methanol from Ethanol), the process requires fractional distillation equipment.

- What is Fractional Distillation? Inside the column, packing material creates multiple stages or theoretical plates where the vapor condenses and re-evaporates. Advanced fractional distillation / reaction distillation systems utilize this principle to achieve purity levels that a simple evaporator cannot match.

- The Reality:This is a fixed asset requiring dedicated utility lines and vertical clearance, but it automates the recovery process for high volumes, reducing the level of manual intervention required.

Phase 3: The Decision Checklist

Use this quick reference to evaluate requirements during equipment selection

| Decision Factor | Choose Rotary Evaporator If... | Choose Distillation Unit If... |

|---|---|---|

| Throughput | You process < 50L per batch | You process > 100L continuously. |

| Solvent Type | You switch solvents frequently. | You run the same solvent mix for weeks. |

| Purity Needs | You just need to strip bulk solvent. | You need > 99% purity from a mixture. |

| Operational Goal | Flexibility & Speed | Consistency & Automation. |

| Space | Benchtop or small floor footprint. | High vertical clearance (Headroom). |

The Hybrid Engineering Strategy

The most efficient pilot plants often reject the binary choice between these two systems. Instead, they employ a hybrid workflow.

Step 1 : The Rotary Evaporator is used for initial solvent trials and residue analysis to define vacuum and temperature parameters.

Step 2 : This data is used to design the scaled-up Industrial Distillation Unit. Reliability in this transition relies on material consistency. Using Borosilicate Glass 3.3 across both stages ensures that chemical resistance remains constant from the 5L flask on the bench to the industrial pipeline in the plant. This continuity prevents unexpected corrosion issues during scale-up.

Conclusion: The Cost of Inefficiency

Selecting the right solvent recovery system is a balance of capital expenditure and operating expense. While a Rotavap is cheaper upfront, using it for high-volume production can be costly in the long run.

Consider the Operational Math :

Illustratively, a standard 20L Rotavap might require an operator to manually refill and empty the flask multiple times to match the output of a small continuous unit. This could represent hours of skilled labor per shift, compared to the minimal monitoring required for a continuous column.

When evaluating the next project, look beyond the brochure price. Calculate the cost of labor, downtime, and energy efficiency to determine the true Return on Investment (ROI). Technical teams are typically available to review solvent stream data and assist with system sizing.

For a detailed evaluation of your facility’s requirements, Contact us.