Rotary Film Evaporator is essentially a thin film evaporator. The rotating flask continuously covers a large surface area with a thin film which is ideal for rapid heat transfer. Fortuitously, the thin film also ensures uniform heat distribution without local heating. The facility to work the unit under full vacuum further facilitates evaporation at as low temperature as possible. That is to say, both boiling point and residence time are significantly reduced. These features combined, renders rotary film evaporator to be ideally suited for evaporation of heat sensitive material. It is equally successful for evaporation of suspension in crystallization processes, drying of powder/ granules etc.

Rota Evaporator finds wide use from small scale laboratory set-ups to industrial operation. Goel Rotary Film Evaporator (GRFE) is preferred by both research and production facilities and has been used by laboratory and chemical, pharmaceutical and biotechnological industries.

Goel Rotary Film Evaporators are completely self contained units consisting mainly of :

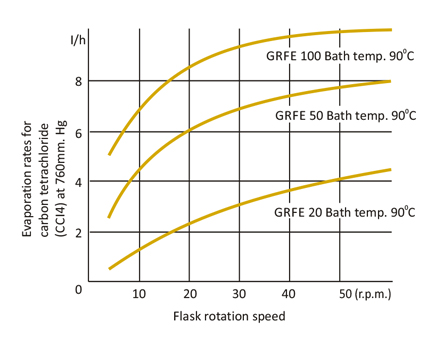

The performance of rota-evaporator depends on various parameters such as temperature differential between bath and contents of flask, RPM, flask capacity and working pressure. An indicative comparison of boil-up of CCI4 rates for 20L, 50L and 100L is given in above figure.

| Model | Rotating Flask Capacity (ltrs.) |

Rotating Speed (rpm) |

Electric Motor Rating |

Condense Cooling Area (M2) |

Receiver Flask Capacity (ltrs.) |

Power Supply (Volt/Hz) |

Bath Rating KW |

|---|---|---|---|---|---|---|---|

| GRFE 5 | 5 | 20-280 | 180 Watt | 0.2 | 2 | 230 V, 50 Hz 1 Phase | 2 |

| GRFE 20/ GRFE 10 | 10 | 20-135 | 0.25 HP | 0.5 | 10 | 415 V, 50 Hz 3 Phase | 4 |

| GRFE 50 | 5 | 20-135 | 0.50 HP | 1.5 | 20 | 415 V, 50 Hz 3 Phase | 6 |

| GRFE 100 | 100 | 20-90 | 1 HP | 2.5 | 50 | 415 V, 50 Hz 3 Phase | 12 |

GOEL brand is associated with quality & reliability and as a company is trend-setter in this business in India.

20 Liter Unit can be supplied with adjustable 10Ltr. Main Flask in 20Ltr. Rotary Film Evaporator so it can be operated at lower volume as and when required.

5 Liter Unit can Accommodate Interchangeable 1, 2, 3, & 5 Liter Flasks. Main flasks will be 5 Liter. So, it can be operated at lower volume as and when required.

20 Liter Unit can be supplied with adjustable 10Ltr. Main Flask in 20Ltr. Rotary Film Evaporator so it can be operated at lower volume as and when required.

5 Liter Unit can Accommodate Interchangeable 1, 2, 3, & 5 Liter Flasks. Main flasks will be 5 Liter. So, it can be operated at lower volume as and when required.