A wiping film evaporator – Falling Film Absorber is a type of evaporator used for separation of liquids, particularly heat sensitive products like vitamins, hormones, enzymes or aromatic substances. It achieves effective heat transfer and controlled evaporation and residence time. This can be avoided if the reactions are carried under vacuum which allows the working temperature to be lowered, and need efficient heat transfer. Falling Film Absorber a Shell & Tube heat exchanger to Absorb forming a thin liquid film on the inner surface of tube. In which both gases to be absorbed & absorbing liquid flow co-currently downward for extraction of heat by circulation of coolant in the Shell side application in NOX GAS e.g. HCL, HBr, SO2, HBr etc.

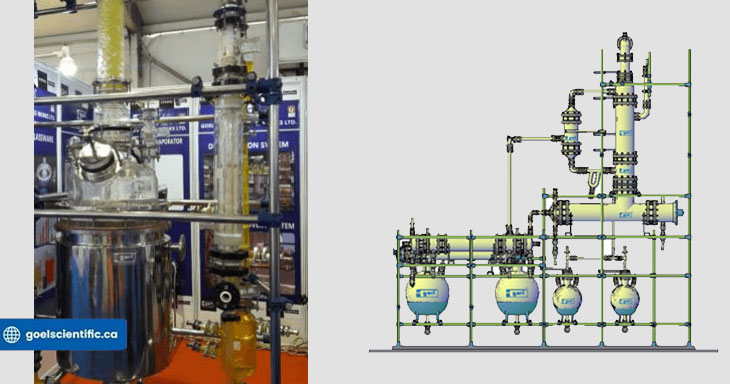

For these, Goel Scientific Inc. introduces a specially design, have range of Evaporators & Absorber made of Borosilicate Glass & PTFE Contact parts. The range varies from laboratory size (80DN) to production plants (300DN). It consists of a cylindrical body and a rotor that rotates at high speed, creating a thin film of liquid on the inner surface of the cylinder.

Widely used in chemical & pharmaceutical industries requiring precise control over reaction, such as aromatics substances & pharmaceutical development. These controlled environment facilitates effects efficient exploration & optimization of various chemical reaction.

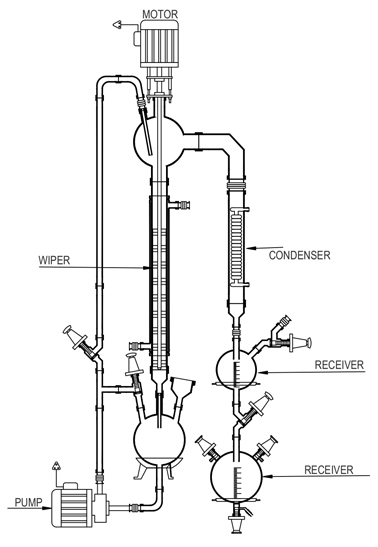

Design of Wiped Film Evaporator

The core of the unit is a rotating, fully corrosion resistant wiper system. This has four rows of PTFE wipers. These rows of wipers are divided into vertical segments and each wiper is mounted between two glass rods.

A liquid distributor is located above the wipers. It distributes the medium, fed in through the feed pipe, uniformly around the circumference of the evaporator before the medium is finally picked up by the wiper system itself.

The evaporator has a vapour outlet which can be connected to a decondensing coil condenser and a receiver. The drive used for the wiper system is a standard geared-motor with AC speed regulator. The wiper shaft is sealed by means of a mechanical seal. The evaporator body is constructed as a jacketed pipe. For heating, thermal oil upto 160°C can be circulated in the jacket.

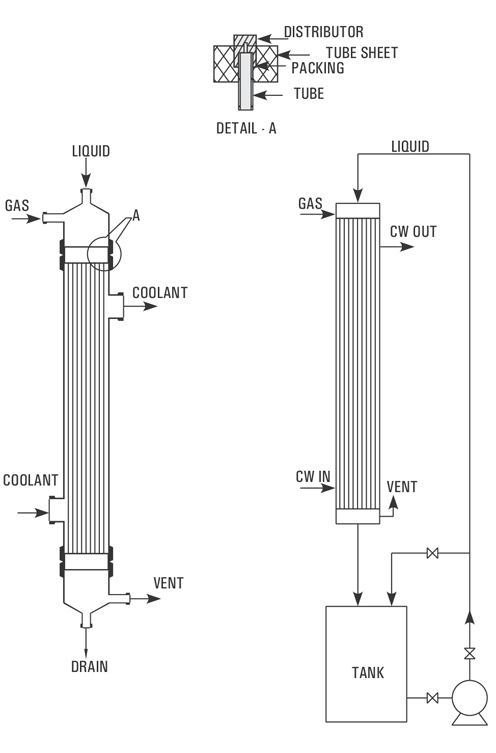

Design of Falling Film Absorber

This is achieved in a Falling Film Absorber which is essentially a shell & tube heat exchanger in which both gases to be absorbed and absorbing liquid flow co-currently downward for extraction of heat by circulation of coolant in the shell. The absorbing liquid is circulated through a tank till desired concentration is achieved. The liquid flows at rate that throws on flow of liquid but instead, describes by gravity along the inner walls of the tubes as a thin film.

How does Falling Film Absorber work?

The equipment works as a number of vertical cooled columns in parallel and each tube is provided with a distribution system on top effect uniform distribution of hot liquid and gas and also formation of a thin liquid film on the inner surface of the tube.

A Falling Film Absorber are radically efficient devices when it comes to very high transfer coefficient & unlimited mass transfer including material designing, which is Borosilicate Glass & PTFE contact parts ensure corrosion / contamination free operation. Shell & Tube Heat Exchanger.

A Wiped Film Evaporator are incredibly efficient devices when it comes to mixing, dispersing, homogenizing, and optimizing chemical reactions on a laboratory scale. They facilitate corrosion- resistant qualities, a clear view of the reaction process, and good performance in vacuum and pressure. These reactors are popular for many applications like Organic & pharmaceutical development because they increase productivity, precision, and total repeatability.

A Wiping Film Evaporator-Falling Film in The USA & Canada

WHY CHOOSE GOEL – A FILM EVAPORATOR?

When considering a Wiping Film Evaporator – Falling Film Absorber for chemical industrial or laboratory needs, The Goel Scientific Film Evaporator stands out as a superior choice. Meticulously designed by industry experts, this reactor engineer to offer users exceptional control over pressure, high performance, and utmost safety. Goel Scientific Company leverages its extensive expertise in scientific glass fabrication & its proficiency in catering to diverse chemical processing industries to create a state-of-the-art system with several distinct advantages.

- Safety Assurance: The Evaporator prioritizes safety by incorporating a protective cage and an underpressurized design to ensure optimum safety standards. These safety measures are integrated to safeguard both the user and the integrity of the processes carried out within the system.

- Visual Monitoring: An all glass body construction enables real-time visual monitoring of the ongoing processes. This transparency allows users to observe and analyze reactions as they progress, ensuring a comprehensive understanding of the processes taking place inside the reactor.

- Wide Temperature Range: The Goel Scientific Company Film Evaporator offers a wide process temperature range, from 90°C to 200°C (with the option to reach up to 300°C). This expansive temperature range allows the reactor’s versatility, enabling it to accommodate a variety of processes requiring specific temperature conditions.

- Efficient Stirring and Mixing: Equipped with a high-speed motor capable of reaching up to 1000 revolutions per minute, the reactor ensures efficient stirring throughout handling of substances. This feature is particularly beneficial for handling products with a wide range of viscosities, ensuring excellent heat transfer within Automation on Request the system.

Advantages of Wiped Film Evaporator

- High Efficiency: Wiped film evaporators offer high evaporation rates.

- Heat-Sensitive Materials: Wiped film evaporators can process heat-sensitive materials without damaging them.

- Minimal Fouling: Wiped film evaporators are designed to minimize fouling, reducing the need for cleaning and maintenance.

- Small Footprint: Wiped film evaporators have a small footprint, making them ideal for use in confined spaces.

- Controlled residence time.

Advantages of Falling Film Absorber

- The heat of absorption is continuously removed. This ensures better absorption and product concentration as compared with conventional packed towers.

- Low residence time and operating temperature ideally suited to heat sensitive materials.

- Borosilicate glass and PTFE contact parts ensure corrosion / contamination free.

- Capable of operating from zero to maximum gas flow rate.

- Ease of installation due to light weight.

- Trouble free and consistent performance with minimal attention.

- Wide application e.g. HCL, HBr, NH3, SO2, H2S, Br2 etc.

- Negligible pressure drop compared to conventional columns.

- Compact design. Sleek and slender column.

- Both heat and mass transfer operations are incorporated in a single equipment.

- Very high heat transfer coefficient as the liquid falls in steady flow.

- Single pass operation. Heat is minimized due to high velocity and ease of cleaning by simple acid circulation.

Applications of Wiped & Thin Film Evaporator:

Wiped & Thin film evaporators are used in a wide range of applications, including:

- Food and Beverage Industry: Wiped film evaporators are used in the food and beverage industry to concentrate and separate various liquid products such as fruit juices, milk, coffee extracts, and other liquids. They are also used in the production of alcoholic beverages such as whiskey and rum.

- Pharmaceutical Industry: Wiped film evaporators are extensively used in the pharmaceutical industry for the concentration and purification of drug solutions, solvent recovery, and the removal of impurities. They are also used in the production of vitamins, amino acids, another organic compounds.

- Chemical Industry: Thin film evaporators are used in the chemical industry for the processing of high boiling point compounds such as resins, polymers, and other specialty chemicals. They are also used in the production of fragrances, flavours, and other aromatic compounds.

- Cannabis Industry: Wiped film evaporators are used in the cannabis industry for the extraction and purification of cannabinoids and trepans from the plant material. They are also used in the production of cannabis concentrates such as distillates, isolates, and tinctures.

- Petrochemical Industry: Falling Film Absorber are used in the petrochemical industry for the processing of heavy oils, waxes, another petroleum products. They are also used in the production of lubricants, greases, and other specialty petroleum products.

- Environmental Industry: Wiped film evaporators are used in the environmental industry for the treatment and purification of industrial waste-water and other contaminated liquids. They are also used in the recovery of valuable chemicals from waste streams.

How does wiped film distillation work?

A wiped film evaporation machine consists of three main parts: a feed inlet at the top of the device, rotor blades inside a cylindrical heating jacket, and outlets or discharge nozzles for product concentrate and vapor.

The distillation process comprises several steps:

- The raw liquid is poured inside the wiped film evaporator through its feed inlet.

- The evaporator’s rotor blades rotate to evenly distribute the liquid to the machine's heated inner surface and create a thin film.

- The liquid's more volatile compounds evaporate through conductive heat transfer. The vapour flows either counter-currently or co-currently through the rotor blades.

- The vapour exits the machine through its vapor outlet. It awaits condensation or further processing, like fractionation.

- The liquid's less or non-volatile compounds exit the machine through its other discharge nozzle. These compounds include salts, chlorophyll, and wax. Since wiped film distillation usually occurs within one machine, manufacturers of oil, chemical, and beverage products can save on facility space and additional equipment and instruments.

Final Thoughts: Thin film evaporators are an important tool for processing heat- sensitive materials in a variety of industries. They offer high efficiency, minimal fouling, and a small footprint, making them ideal for use in confined spaces. However, they are more expensive than traditional evaporators and require regular maintenance to ensure proper operation. If you are considering using wiped film evaporator for your application, it is important to understand the design, operation, and limitations of this type of evaporator.

1. What safety precautions should I take when working with Falling Evaporator?

Always wear the proper safety gear, such as gloves, a face shield, and safety goggles. When feasible, use glassware with a PVC coating. Cover flasks, drawers, and desiccators with mesh or tape if not available.

2. How do I clean and maintain a Falling Film Absorber?

More satisfying results will come from using a cleaning powder with a little abrasive effect on very unclean glassware. Certainly, a brush can thoroughly clean every portion of the glassware throughout the washing process.

3. Can I customize a Film Evaporator to meet my needs or add additional features?

Yes. Film Evaporator are built from a variety of materials according to your needs. All you have to do is search for the Custom laboratory glassware manufacturer near me, and Goel Scientific will be available at your service.

Need top-notch industrial glassware manufacturers? Goel Scientific Glass a reliable and renowned name when it comes to top-grade lab equipment. Contact us today for a quote.

Salient Features Film Evaporator.

- Film Evaporators made from Germany Raw Material.

- Stirrer with suitable mechanical seal/stuffing box/magnetic seal.

- Skid Mounted and quick release clamp for easy installation & removable of glassware.

- Suitable for vacuum condition

- Flush bottom with minimum dead volume.

- Overhead Stirrer geared motor with built-in speed controller & display.

- Measurement Marking on the vessel.

- Interchangeable Stirrer anchor, propeller, turbine Digital temperature indicator

- All This Evaporator are designed GMP.

| Sr. No. | Nominal Size (mm) | Absorber Area (m2) | No. Of Tubes/Tube OD (mm) | Max. Gas Absorption Rate (Pure HCL)* (Kg/hr) | Max. Acid Prod. Rate (As 30% HCL)( Kg/hr) | Height (m) |

|---|---|---|---|---|---|---|

| 1 | 80 | 1.00 | 4/20 | 30 | 100 | 4400 |

| 2 | 100 | 1.76 | 7/20 | 60 | 200 | 4500 |

| 3 | 150 | 4.80 | 19/20 | 150 | 500 | 4600 |

| 4 | 225 | 7.80 | 31/20 | 250 | 833 | 4920 |

| 5 | 300 | 15.30 | 61/20 | 500 | 1667 | 5050 |

| 6 | 400 | 36.00 | 143/20 | 1175 | 3917 | 5300 |

| 7 | 450 | 47.00 | 187/20 | 1500 | 5000 | 5700 |

| 8 | 600 | 84.00 | 333/20 | 2700 | 9000 | 5800 |

| MODEL | SIZE DN (mm) | HTA(M2) |

|---|---|---|

| WFE3 | 80 | 0.35 |

| WFE4 | 100 | 0.47 |

| WFE6 | 150 | 0.70 |

| WFE9 | 225 | 1.06 |

| WFE12 | 300 | 1.41 |