ABOUT OUR COMPANY

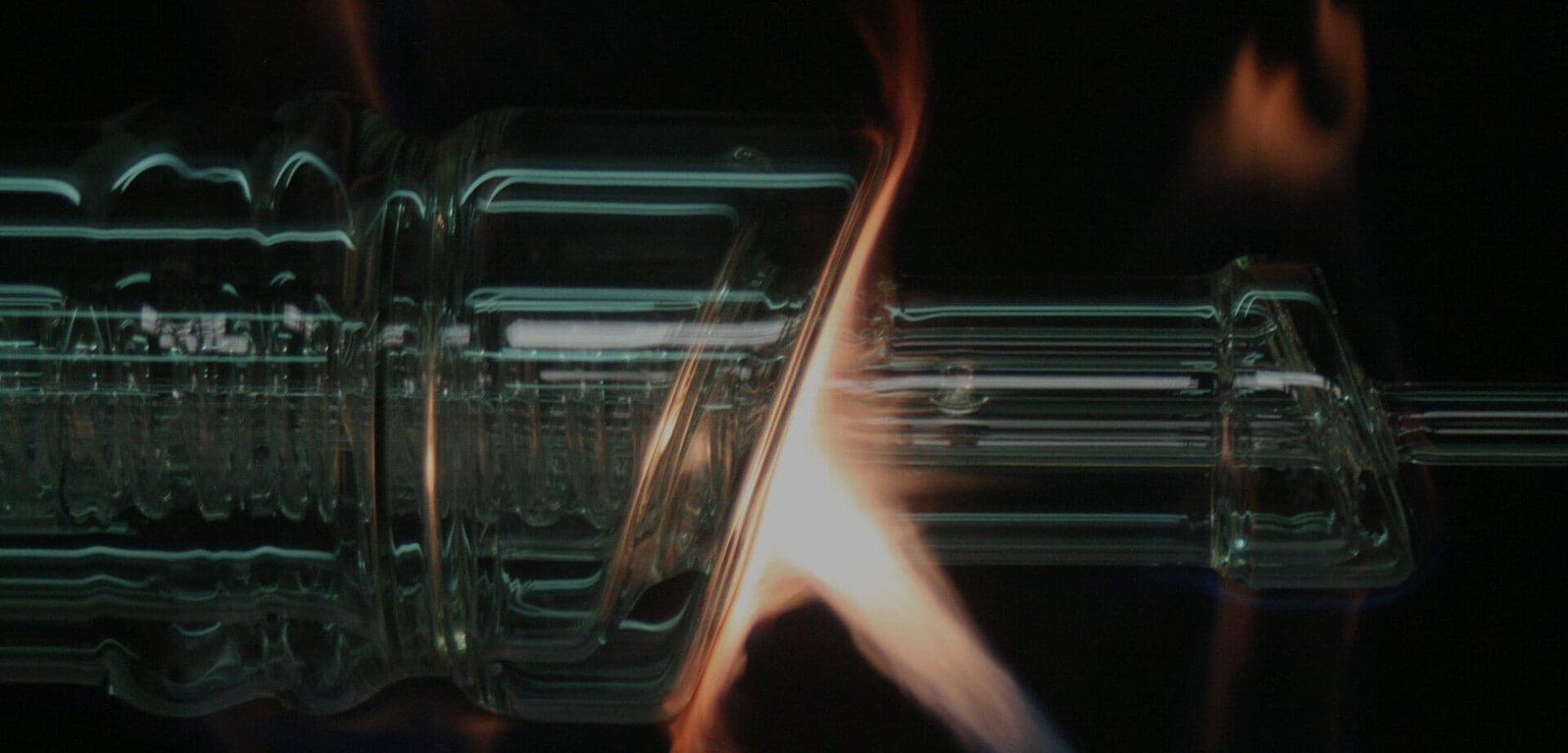

Welcome To Goel Scientific Glass Inc.

Goel Scientific Glass Inc is one of the leading scientific glass fabricators in the world, providing a significant leap for the glass industry in the global market. We have established a presence across all populated continents, representing and supplying our products and services worldwide. At present, we have over 1,100 satisfied customers across the globe.

As a key supplier to the pharmaceutical industry, Goel Scientific Glass manufactures glass reaction systems up to 200 liters in size, complete with all controls and accessory equipment. In addition to our wide-ranging product offerings, Goel Scientific Glass will also fabricate custom laboratory glassware to meet the most demanding customer specifications.